Embrace Prevention Over Planning & Waiting for Equipment Failures

Published : 19 Mar 2024

Many industries often find themselves in a cycle of reacting to equipment failures rather than proactively preventing them. The common approach is to initiate an action plan when a failure occurs or even plan, expecting failures to happen. But what if there was a way to prevent these failures altogether and enjoy a more relaxed and efficient operation?

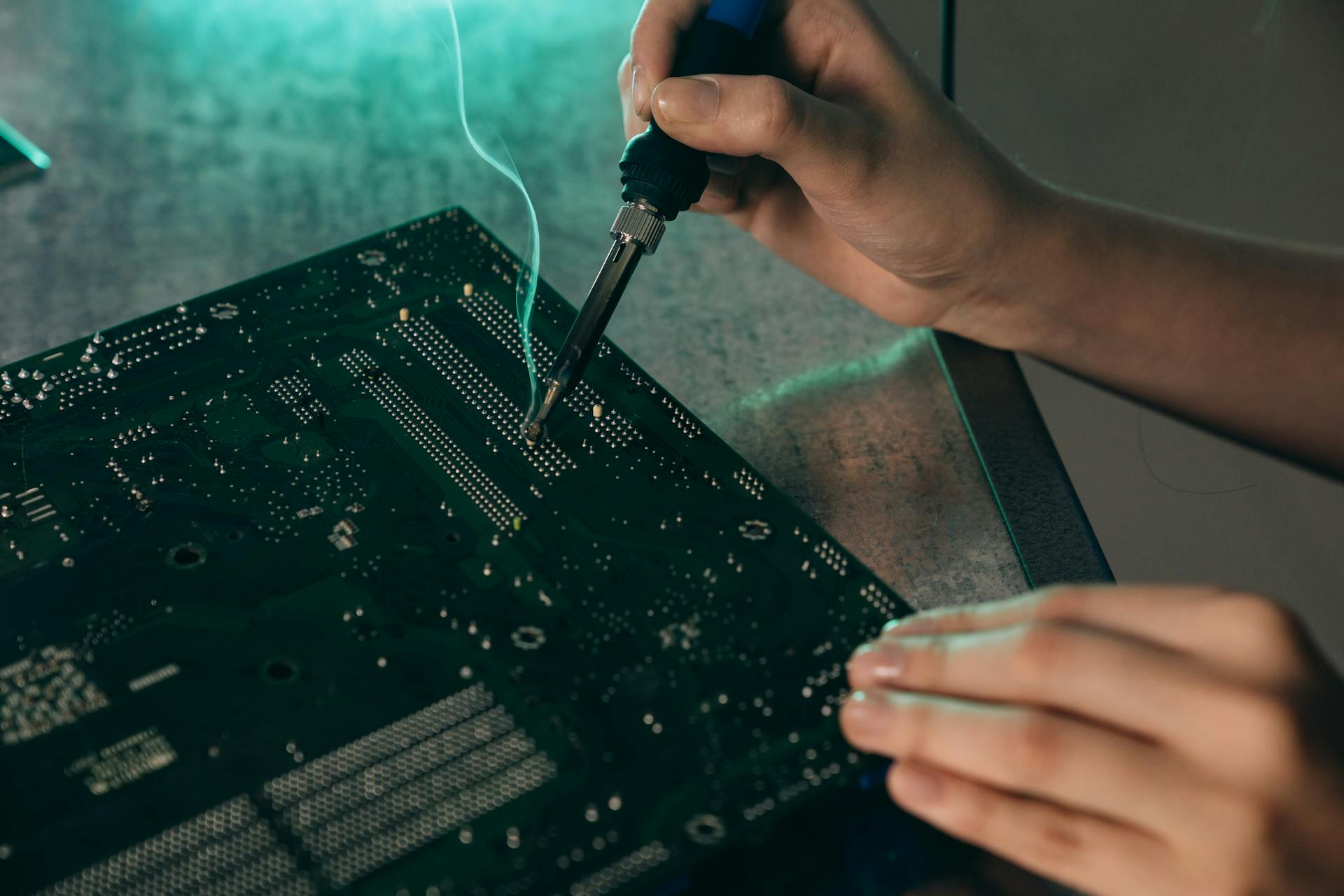

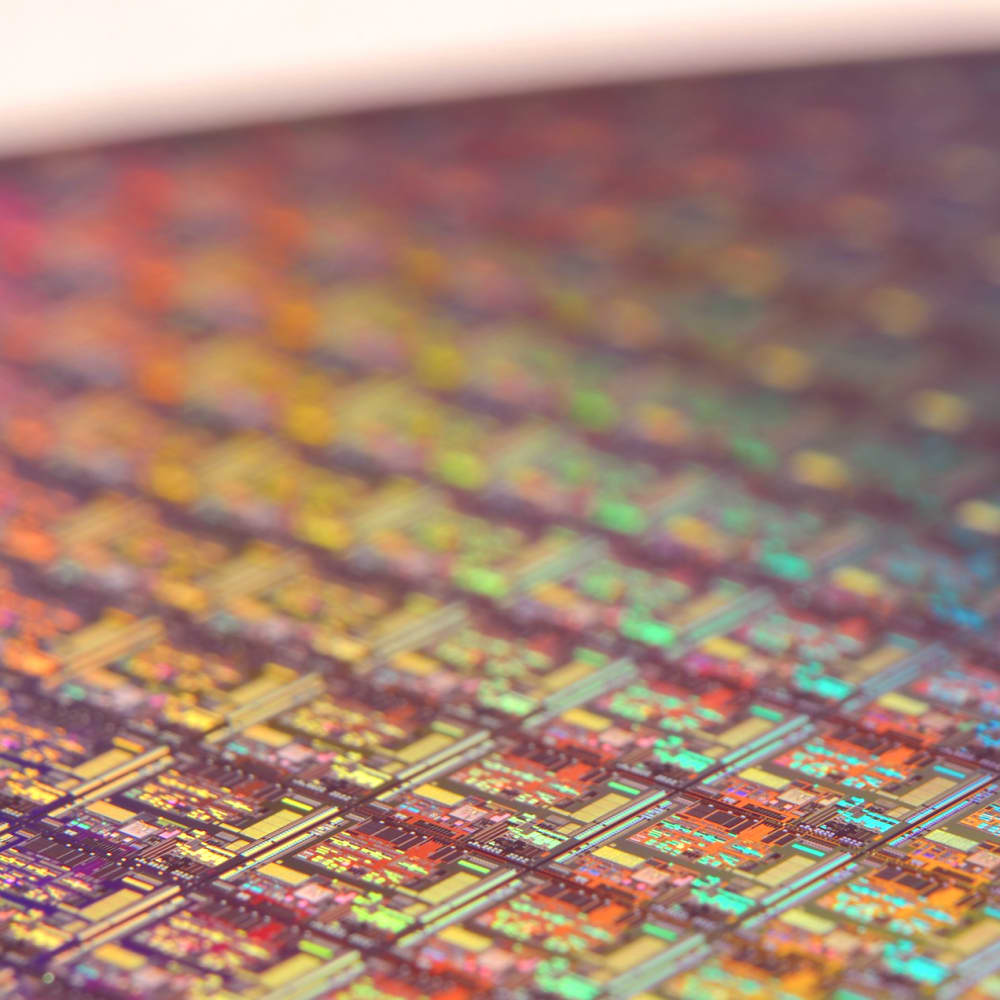

The First Step: Maintain a Corrosion-Free Atmosphere

One crucial step toward achieving a failure-free environment is to maintain a corrosion-free atmosphere where electronics are used. Not only does this help avoid maintenance and unplanned downtime, but it also ensures that equipment warranties remain valid, as they often become void if corrosion is found.

Identifying the Problem

Despite efforts to maintain a corrosive-free atmosphere, gaseous infiltrates can be challenging to spot and stop. This is where proactive monitoring and maintenance become essential.

Choosing the Right Solution

Both passive and active corrosion monitoring units are tailored to your specific requirements. An Active corrosion monitor solution provides real-time data on severity, and at the same time logs the data. Whereas a passive corrosion monitors provide a detailed report of the corrosive environment, at the end of a 30-day exposure period.

Analysis: Active vs. Passive Monitoring

Active corrosion monitors provide instant reports by automatically analyzing corrosion and displaying them, these data are instantly logged and can be taken into any individual system for convenience. The passive sensors offer detailed reports after a minimum exposure of 30 days. It has a datalogger which records temperature and humidity values. This comprehensive analysis helps you understand the corrosion levels and take necessary actions.

Installing a Corrosion-Free Environment Solution

If the severity level is determined to be greater than G1 as per the ANSI / ISA 71.04 – 2013 Standard, an active corrosion control method may be necessary. The Corrosion Control Unit removes corrosive gases from your facility, ensuring a corrosion-free environment for your electronics.

Efficiency Check and Maintenance

The corrosion monitoring unit also serves as an efficiency check for the corrosion control measures you have implemented, ensuring they are working as intended and maintaining a corrosion-free environment. By implementing these methods, you can ensure that your electronics do not prematurely fail, avoiding the need for preparedness for equipment failures altogether.

Contact our experts to learn more and take the first step toward a corrosion-free environment.