Virgin Carbon Vs Impregnated Carbon

Published : 31 Mar 2021

When a fluid enters to the interiors of a solid lattice and sustains, we say that the fluid got absorbed in the solid. When the solid retains the fluid only on the surface of it then the phenomenon is known as adsorption.

When a fluid enters to the interiors of a solid lattice and sustains, we say that the fluid got absorbed in the solid. When the solid retains the fluid only on the surface of it then the phenomenon is known as adsorption.

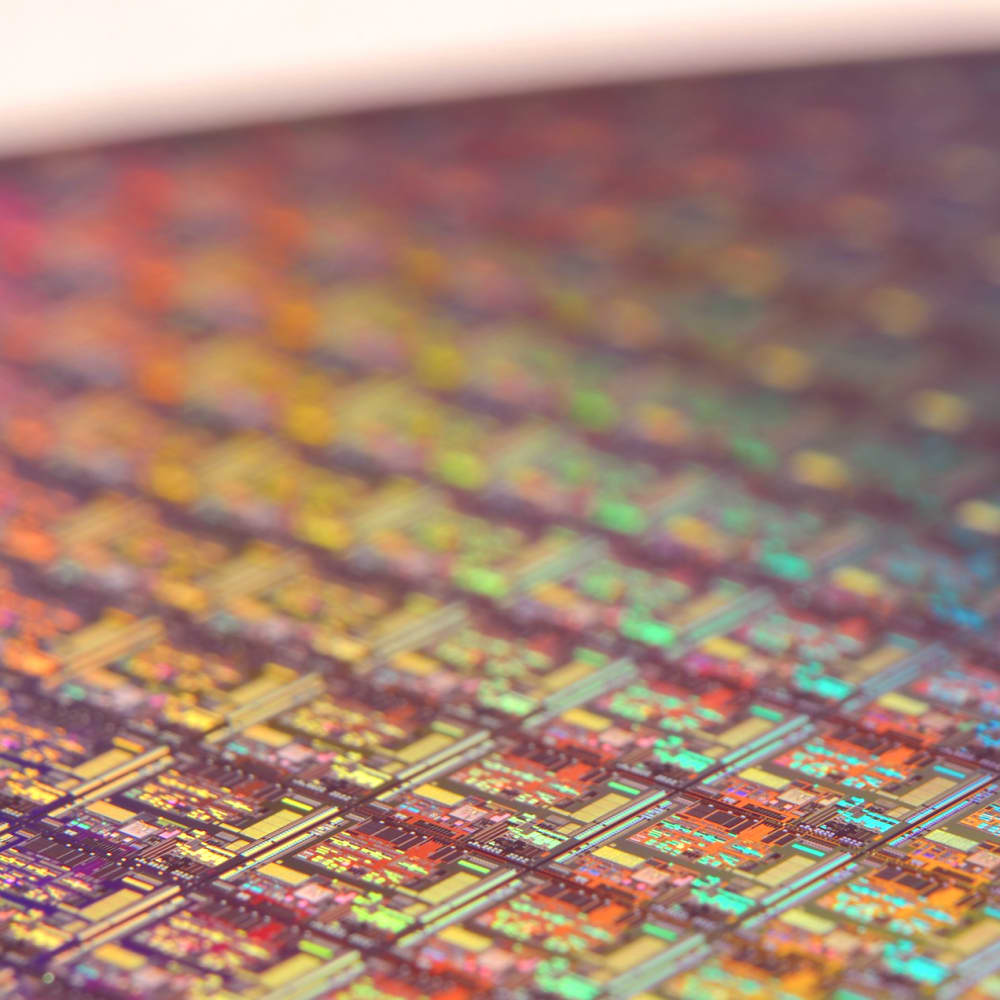

There are two types of adsorption, namely physical adsorption or physisorption and chemical adsorption or chemisorption. Usually, the common phenomena in adsorption are physical adsorption or physisorption. The binding force between the adsorbent and adsorbate is the Weak Vander Waals force, which can be broken even by thermal means. Activated carbon is usually prepared by passing steam through red hot charcoal. This process results in the opening up of several pores in carbon. Moreover, the platelets of the carbon also get realigned. This is usually known as plain carbon or virgin carbon. Activated carbon (coconut carbon) is used for the purification of air and similar gaseous materials.

The adsorption here is simply physical in nature and can be easily expelled by heating. Usually, a uniform layer of the gas gets adsorbed on the inner and outer surfaces of carbon wherein there is a weak attraction between the gas and carbon. As there is no strong bond and a uniform layer is formed in the platelets then the desorption process follows. Thus, plain carbon cannot function as an adsorbent medium after certain stage. Plain carbon adsorbs certain non-polar molecules by physisorption and certain other gases like hydrogen sulphide, sulphur dioxide, oxides of nitrogen etc. to nearly 10% by weight of the carbon used, by chemisorption.

In order to increase the capacity, the adsorbed material has to be removed on the spot. This is only possible if there is a presence of other materials reacting with the adsorbed gas immediately.

This can be achieved by impregnating suitable chemicals to the activated carbon so that the space for adsorption becomes available again and again. The adsorption capacity increases 5 to 10 times as that of plain carbon, if there are enough impregnates in the carbon. Depending upon the quantity of the impregnant, the quantity of the gas adsorbed also gets changed. For instance, for adsorbing hydrogen sulphide, either potassium hydroxide or hydrated copper oxide is used. These kinds of activated carbons are widely used for Air purification, Odour removal and VOC removal applications in various industries like wastewater treatment plant, pharmaceuticals, corrosive gas generating industries, etc. Similarly, for removing ammonia or any mineral acids like phosphoric acid it can be used as impregnant.

For the adsorption of carbon monoxide, the palladium impregnation can be done on the activated carbon. Adsorption of gases like carbon dioxide is quite less with plain / virgin carbon but can be used very effectively with impregnated carbon. If we want to recycle the process, organic primary amines can be practiced. A lot of oxidisable materials which are practically impossible to be removed using plain carbon can be removed very easily with the impregnated activated carbon. Thus, if the impregnant selection is right, let it be any war gas, it can be wiped out using Coconut activated carbon or even Coal based activated carbon at some extent.

At AQOZA, our R&D wing is specialized in developing impregnated activated carbon for various Gas & odour removal applications. Significantly, when it comes to the selection of impregnant, we give preference to land disposable / non-hazardous chemicals that serves & aids immensely in our mission accomplishment, delivering best to society, business and environment.

Also Read:

Why is Coconut Activated Carbon preferred for Air & Odour purification?

How much Green is Coconut Activated Carbon?