How To Prevent Odour from STP Causing Corrosion and Electronic Failures?

Published : 24 May 2024

Odour is a well-known issue that requires attention at sewage treatment plants (STPs), which cause health and safety problems mainly for the workforce. However, beyond the discomfort caused by this, there exists a hidden risk associated with the gases responsible for generating this odour and they need to be addressed.

The odour produced from sewage treatment plants can contribute to corrosion in the electronics and equipment within these facilities. This unexpected relation makes it very important to understand how this odour from STP affects the health, comfort, deterioration of materials and even the failure of electronics.

Understanding Sewage Treatment Plants

The major odour generating area in a sewage treatment plant are wastewater collection systems and sludge treatment area.

Collection system includes sewage receiving channels, screening, grit removal and collection sump. The odour primarily originates from the anaerobic decomposition of organic matter. Major odour causing gases generated are Hydrogen sulphide (H₂S), Ammonia (NH3), Mercaptans and VOCs. Releases of these untreated gases to atmosphere causes potential air pollution and health hazards. (H₂S) is particularly known for its foul smell, even in low concentrations, and contributes significantly to the unpleasant odour experienced in STPs.

How Does corrosion happen?

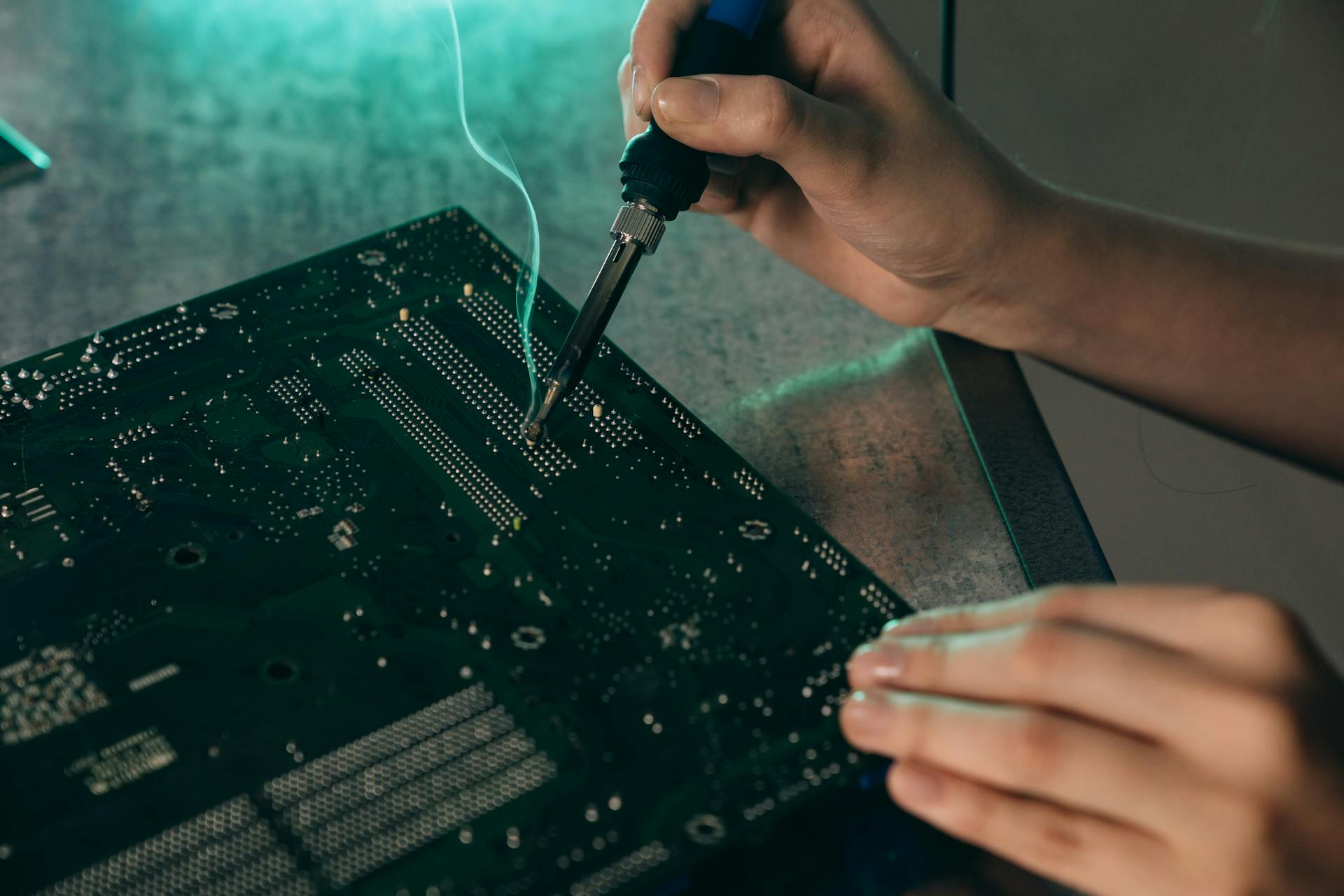

It is crucial to understand how these gases can cause corrosion, which in turn affects the efficient operation of the facility.

Certain gases that are generated from STPs are acidic in nature. For example, H₂S, produced, can react with moisture in the air to form sulphuric acid, making it corrosive.

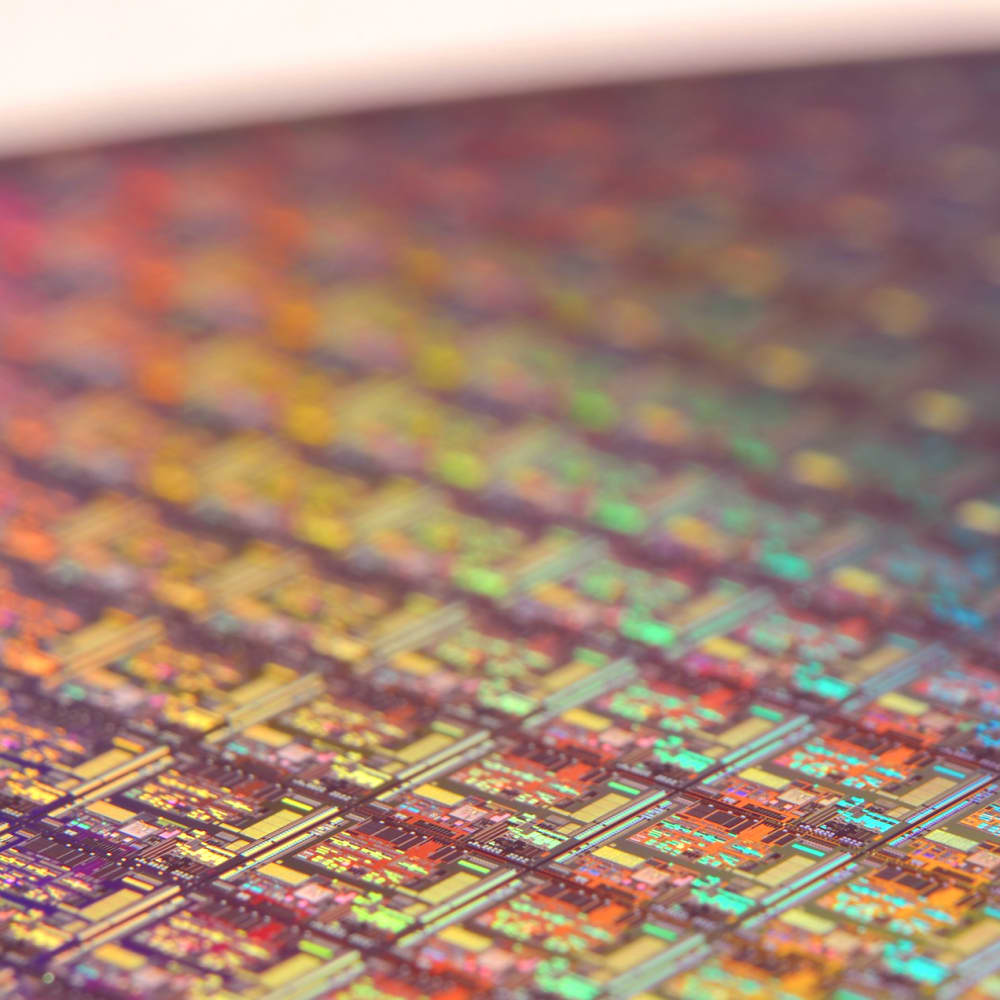

In sewage treatment plants (STPs), important electronic parts, especially those in control panels and sensitive equipment, are more likely to get corroded. Failures in these components can lead to disruptions in the treatment process. This doesn’t stop here, the emitted gases from the STP can be carried away by the wind and this can be taken into the sever room or critical control rooms of the facility thus damaging the electronics present there, causing significant downtime, affecting the facility's operation.

Challenges Arising from Corrosion

The concentration of gases required for corrosive failures are small for electronic components (ppb), while the deterioration of metals and structures needs a little higher concentration. STP produces gases in the level of parts per million (ppm) thus affecting even the structures made of metals. This makes it necessary for periodic maintenance or replacement of high metal structures adding to the cost of operation and maintenance.

The failure of critical electronics can bring down the complete operation of the facility to a halt. This can sometimes cause electronics to failures far from repair.

These untreated odorous corrosive gases can cause:

- Unplanned downtime

- Revenue loss

- More maintenance

- Hazardous working conditions

Gas Phase Filtration: The Ultimate Solution

The above mentioned problem is more than sufficient for any facility to collapse. So finding an appropriate solution is inevitable and one effective approach is implementing Gas Phase Filtration: removing gaseous contaminants from the air that could harmfully affect the occupants, contents or environment of a given space. This is a perfect solution for preventing Odour and corrosion occurring due to acidic gases in STPs.

Contact the experts to know more.