Corrosion Control Strategies for Electronics in Oil & Gas Operations

Published : 30 Aug 2024

Electronic products are essential across all stages of oil & gas operations, including exploration, development, production, and refining processes. Specialized electronics, such as seismic survey systems, pressure sensors, flow meters, and automated control panels, are vital for precise measurements and control within controlled environments, ensuring the reliability of operations throughout the lifecycle of oil deposits, their transportation, and their refinement into fuels and chemical products.

Understanding and implementing effective corrosion control is crucial to ensure the longevity and reliability of these electronics, ultimately saving costs and improving safety.

Importance of Electronics

In the oil and gas industry, the reliability of specialized electronic products is critical. These systems operate in controlled environments, responsible for accurate measurements and the functioning of permanent systems used for data collection, monitoring, and control of essential variables. For instance, well logging systems compile reservoir data within dedicated facilities, providing insights into pressure, temperature, and fluid properties. When these electronics, including control systems and telemetry devices, fail, it can lead to significant operational disruptions.

Corrosive Gases Affecting Electronics

Several corrosive gases emitted during oil and gas operations pose serious threats to electronics even in controlled environments:

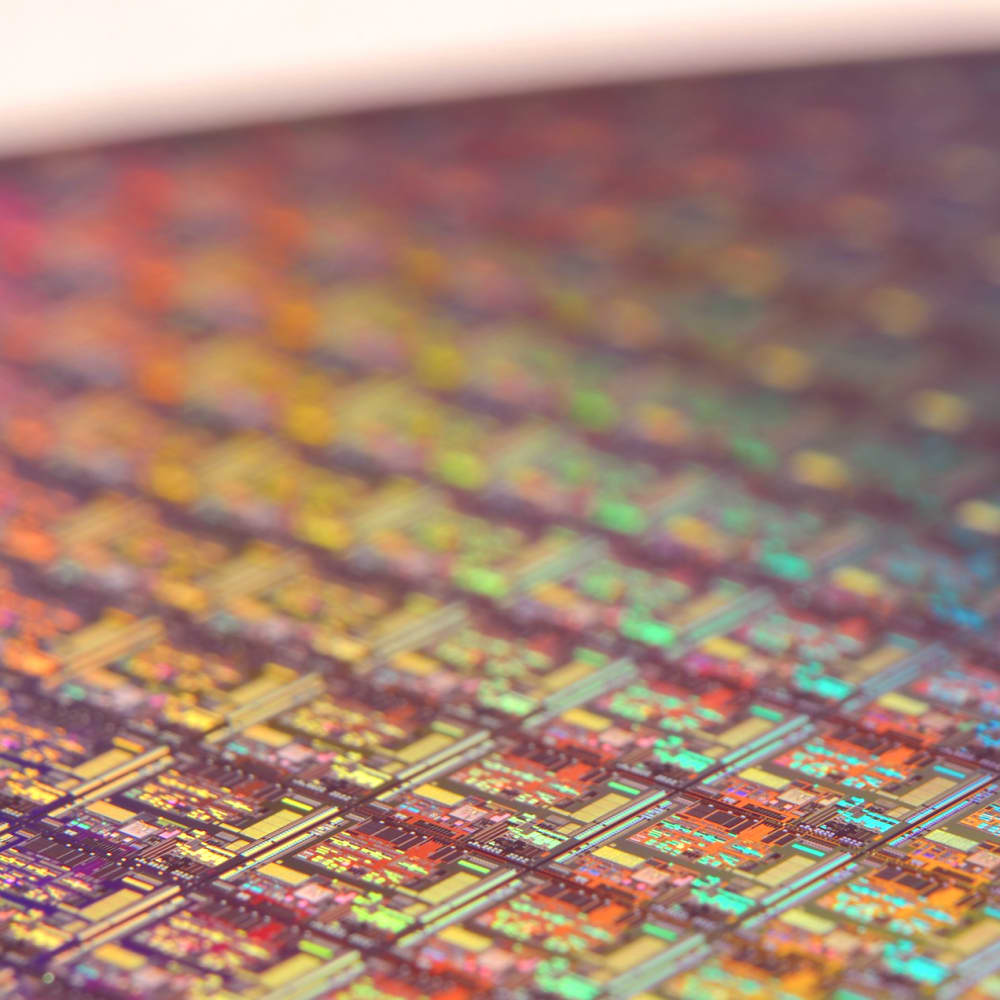

- Hydrogen Sulfide (H2S): Highly corrosive and commonly encountered in drilling and production, H2S can impact electrical connections and circuit boards within drilling systems and production monitoring devices situated indoors.

- Sulfur Dioxide (SO2): Present in refining processes, SO2 can form acidic compounds with moisture, damaging sensors and control systems essential for refining operations in enclosed facilities.

- Chlorides: Found in produced water, chlorides can cause severe corrosion of sensitive electronic components, particularly in sub sea equipment and pressure transmitters used in controlled environments.

Impact of Corrosion on Electronics

- High Maintenance Costs: Corrosion leads to frequent repairs and replacements of critical equipment like control panels and electronic actuators, significantly increasing maintenance expenses. For example, the failure of permanent monitoring systems in an indoor setting can result in costly downtime during critical production phases.

- Production Downtime: Malfunctioning electronics, such as data loggers and monitoring devices, can cause operational delays. In drilling operations, if real-time monitoring systems fail due to corrosion, it can lead to inaccurate assessments of well conditions, impacting overall productivity.

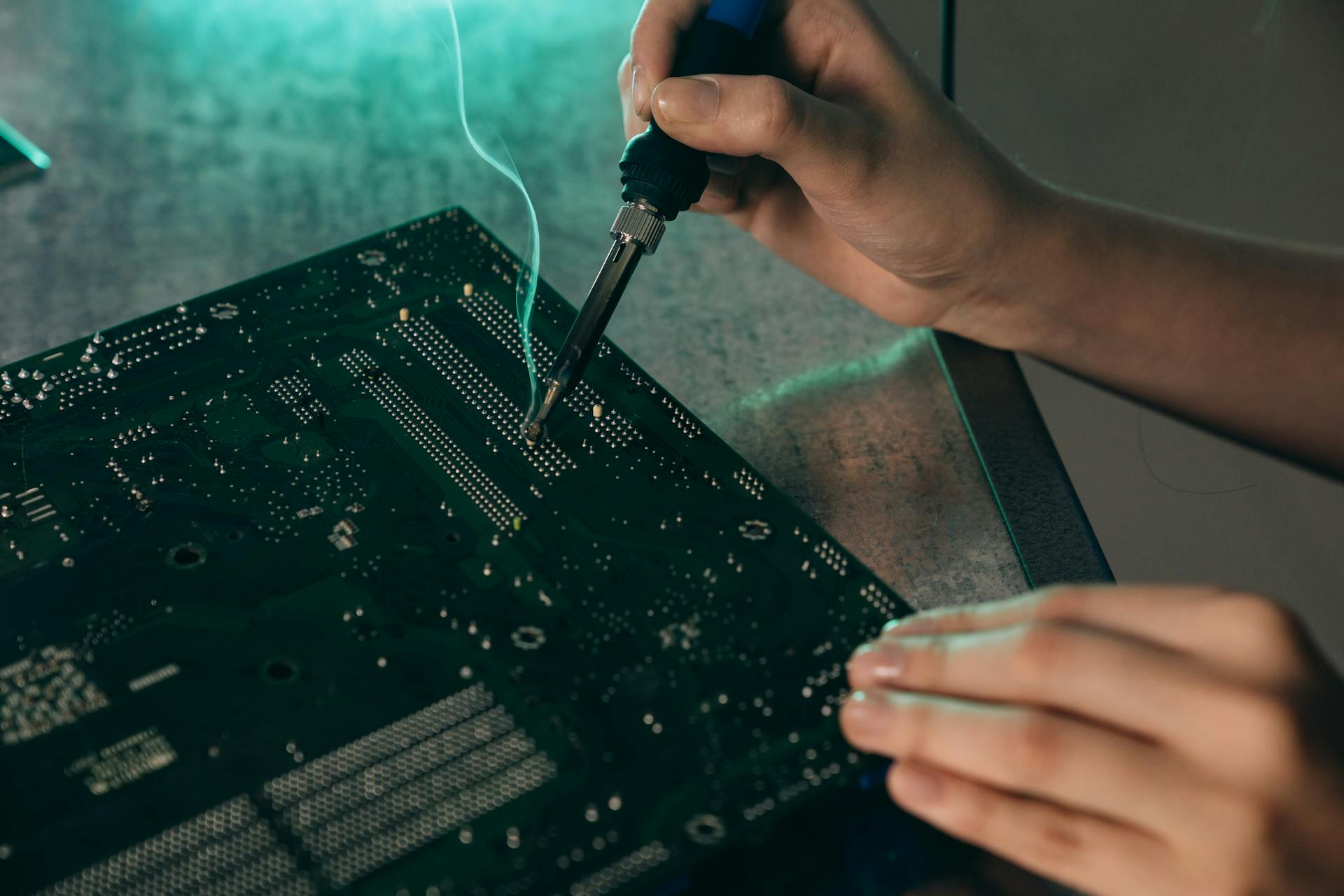

Challenges in Electronic Component Production

- Low Production: Many specialized components, such as custom sensors, PCB assemblies, and field instruments, are produced in small quantities, making them expensive and not readily available. This is particularly challenging for process control systems in refineries, where specific electronics are needed to ensure compliance with operational standards.

- Increased Costs: The lengthy design and certification process (2-4 years) for complex systems like automation controllers combined with a long service life (5-10 years) further elevates costs, especially when corrosion issues necessitate more frequent replacements.

- Supply Chain Issues: Manufacturers often withdraw from the market, forcing companies to rely on off-the-shelf parts that may not always meet specific requirements or be in stock, complicating maintenance for critical systems like safety controls and gas detection systems used in controlled environments.

Importance of Corrosion Control

- Extended Equipment Life: Effective corrosion control extends the lifespan of electronic systems, such as sensors and monitoring systems, reducing the need for frequent replacements. Implementing real-time corrosion monitoring units can provide insights into the severity of corrosive environments, adhering to ANSI/ISA 71.04 standards, which is crucial for maintaining the integrity of sub sea control systems in controlled settings.

- Cost Efficiency: Minimizing corrosion-related damage lowers maintenance costs and prevents costly downtime, protecting vital equipment like data acquisition systems and control valves situated indoors. This is particularly important in production monitoring, where even minor issues can lead to significant operational losses.

- Performance: Ensuring the durability of electronic systems enhances operational stability and safety. This is crucial in refining operations, where control systems manage complex processes and must perform reliably within controlled environments under varying conditions.

Conclusion

In the oil and gas industry, protecting electronics from corrosion is not just a technical necessity; it is a strategic imperative. By implementing reliable corrosion monitoring and control measures, such as real-time monitoring units and corrosion-resistant materials, businesses can safeguard their equipment within controlled environments, ensure continuous operation, and reduce maintenance costs.

Investing in corrosion prevention is essential for maintaining productivity and profitability in this high-demand industry. Still confused?