Corrosion Control in Telecommunication Equipment

Published : 20 Aug 2024

In today’s rapidly evolving and interconnected world, telecommunications play a critical role in facilitating communication and supporting essential services for individuals and businesses alike. Yet, beneath this seamless connectivity lies a hidden challenge that often goes unnoticed: the gradual deterioration of electronic components in telecommunications systems due to environmental factors. This silent threat can compromise the integrity of these systems, leading to unexpected operational disruptions, expensive repairs, and a potential decline in customer trust.

Factors accelerating corrosion

To ensure the longevity and reliability of electronic components in telecommunications, it is vital to recognize this underlying issue and understand the various contributors to corrosion while implementing effective preventive strategies.

Environmental Impact: The Role of HVAC and Humidity

- One of the most significant contributors to corrosion in telecommunications infrastructure is particularly through HVAC systems that regulate temperature and humidity as these systems can also allow gaseous infiltrates to enter the facilities.

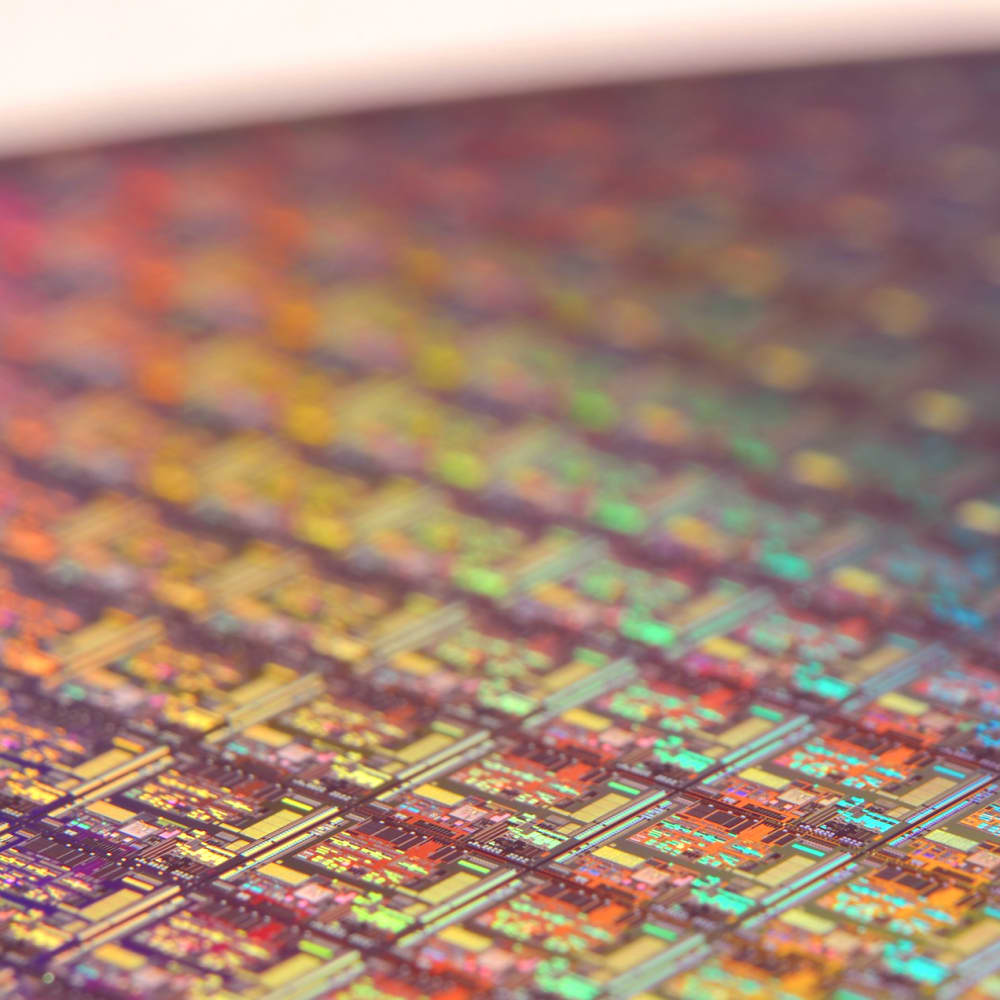

- High humidity levels (over 70%) can lead to the deterioration of printed circuit boards (PCBs) and zinc whisker growth, while low humidity (below 20%) can cause electrostatic discharge (ESD), affecting component performance.

- Additionally, gaseous infiltrates, such as chlorine emitted from PVC coatings used in cable insulation and sheathing, further accelerate corrosion processes, posing a serious threat to electronic components.

Temperature Fluctuations:

- Rapid temperature changes can increase the risk of condensation, exposing metal components to moisture and accelerating corrosion.

Pollutants in the Atmosphere:

- Areas with high levels of atmospheric contaminants, such as sulfur dioxide, also contribute to corrosion, further complicating the challenges faced by telecommunications infrastructure.

Key Equipment Prone to Corrosion Within Facilities

Even within controlled environments such as data centers and telecommunication facilities, several key pieces of equipment are particularly vulnerable to corrosion:

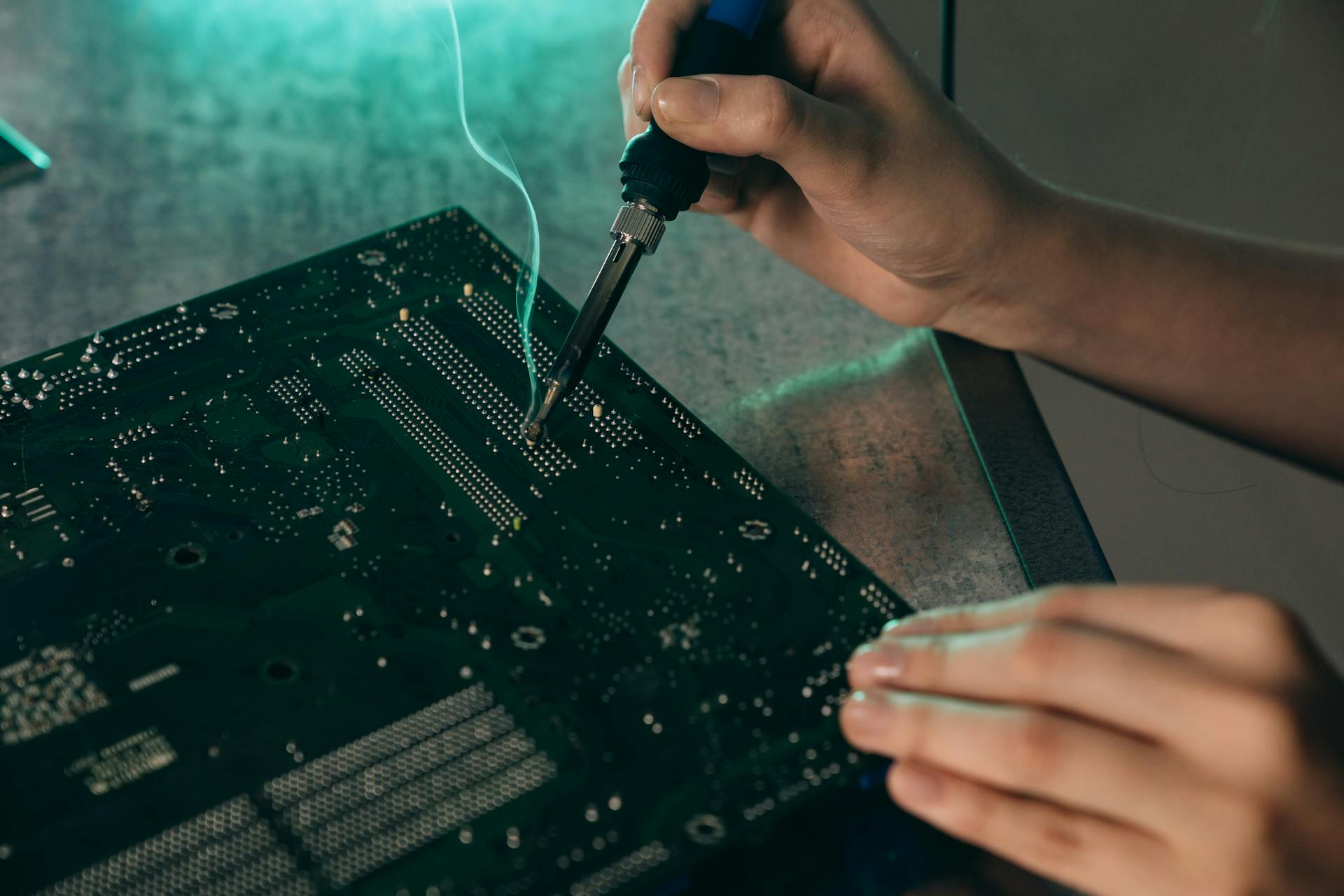

Base Transceiver Stations (BTS): Located within dedicated telecom rooms, BTS units are crucial for cellular network operations. Despite being housed indoors, they can still suffer from corrosion of components like power supplies and circuit boards due to humidity and airborne contaminants.

Indoor Cabinets and Racks: These house critical equipment, including routers, switches, and backup power supplies, within telecommunication facilities. Corrosion can occur due to internal humidity fluctuations and contaminants from HVAC systems, affecting the performance and longevity of these components.

Central Office Switching Equipment: Essential for managing telecommunications traffic, switching equipment located in central offices is susceptible to corrosion, particularly in high-humidity environments where electrostatic discharge (ESD) and other corrosion-related issues can arise.

Fiber Optic Termination Panels: Though typically installed in controlled indoor environments, these panels where fiber optics connect to electronic systems can be compromised by corrosion, especially if exposed to high levels of humidity or contaminants from nearby materials.

Embracing Modern Preventive Strategies

As the telecommunications sector evolves, new effective solutions need to be adapted. New technologies can significantly reduce risks, including:

- Advanced Environmental Monitoring: Implementing real-time corrosion monitoring systems continuously measures corrosion rates in an environment. This provides crucial data about temperature and humidity and this Continuous data analysis enables timely adjustments to environmental controls, preventing potential corrosion issues.

- Air Filtration and Corrosion Control Solutions: Dedicated corrosion control units that utilize advanced air filtration techniques can effectively reduce particulate and gaseous contaminants while appropriately giving data on humidity level and temperature. These solutions enhance air quality and protect sensitive equipment. Regular maintenance and filter replacements are essential to ensure optimal performance and long-term protection against corrosion.

By understanding the depth of corrosion and its contributing factors, including environmental influences, telecommunications companies can take proactive steps to protect their infrastructure. Implementing innovative preventive measures along with traditional measures will enhance the reliability and longevity of equipment, ensuring uninterrupted communication services in our ever-connected world.