Combat Odors and Corrosive Gases with Gas-Phase Filtration

Published : 08 Jul 2024

In today's industrial and commercial environments, maintaining high air quality is essential for health, safety, and operational efficiency. Harmful gases can affect productivity, equipment longevity, and the well-being of employees. Gas-phase filtration offers a robust solution to these challenges by effectively removing gaseous pollutants from the air.

What is Gas-Phase Filtration?

Gas-phase filtration involves the use of specialized filtration media and systems to capture and remove contaminants in gaseous phase that are harmful for life, machinery and environment. Gas phase filtration equipment tends to work in two ways. Firstly they are used as control devices to capture the gasses at source to prevent emissions. Secondly, they are used as protective devices which prevent the gaseous infiltrates from penetrating inside your facility.

Benefits for Your Business

- Enhanced Air Quality: Gas-phase filtration significantly improves indoor air quality by eliminating harmful gasses. This not only creates a healthier environment but also enhances overall workplace comfort.

- Health and Safety: By reducing exposure to toxic gases, gas-phase filtration helps prevent respiratory issues and other health problems among employees and customers. This ensures compliance with health and safety regulations.

- Operational Efficiency: Cleaner air protects sensitive equipment from corrosive gases, reducing the risk of damage and maintenance costs. This leads to fewer downtime and prolonged equipment lifespan.

- Regulatory Compliance: Many industries face stringent air quality regulations. Implementing gas-phase filtration helps businesses meet these standards and avoid potential fines and sanctions.

Addressing Specific Challenges

- Odor Control: Industries such as wastewater treatment plants (STP), water treatment plants (WTP), and food processing often deal with unpleasant and potentially harmful odors. Gas-phase filtration systems effectively remove odorous compounds like hydrogen sulfide (H2S), ammonia, and organic sulfur compounds, ensuring a more pleasant and safe working environment.

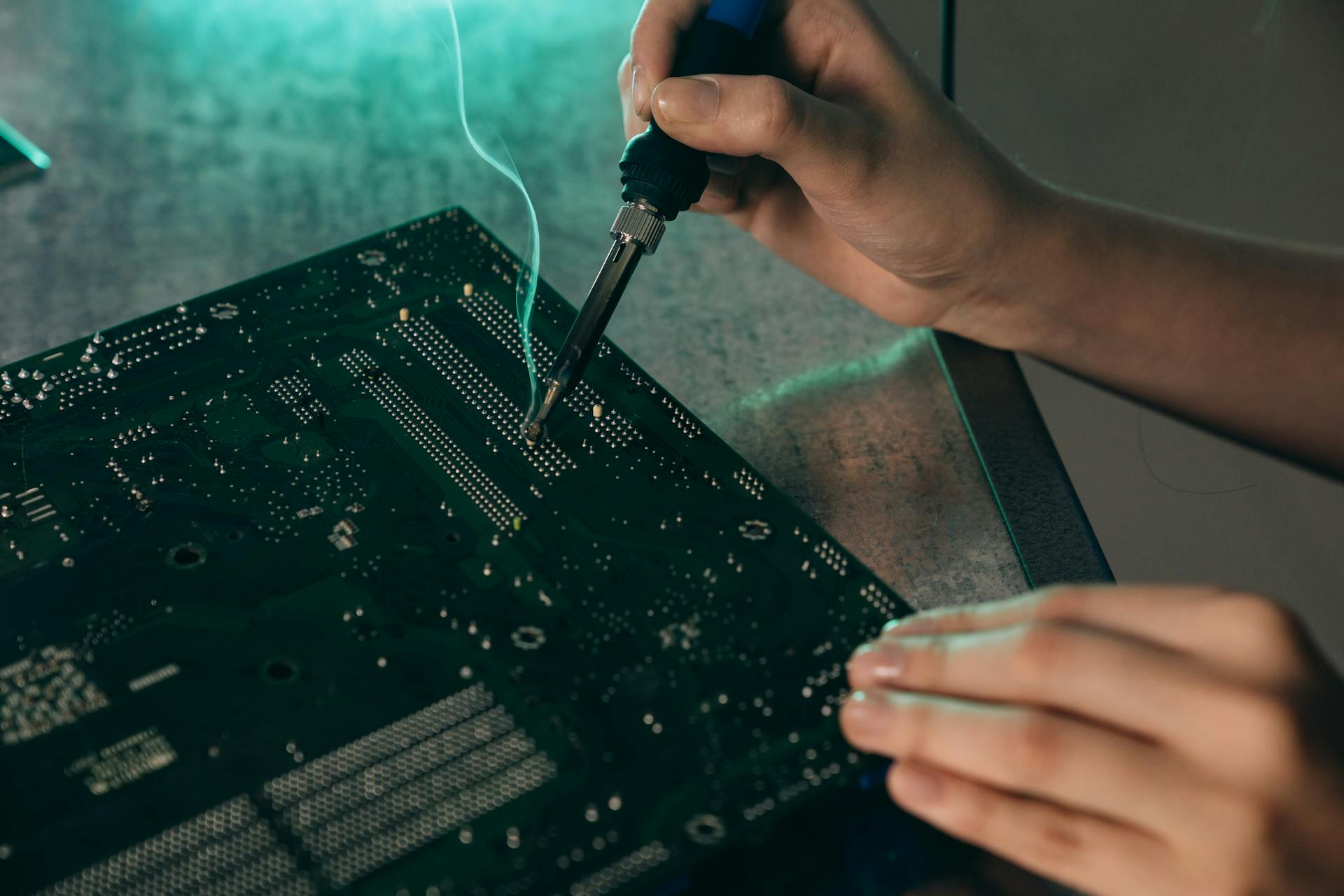

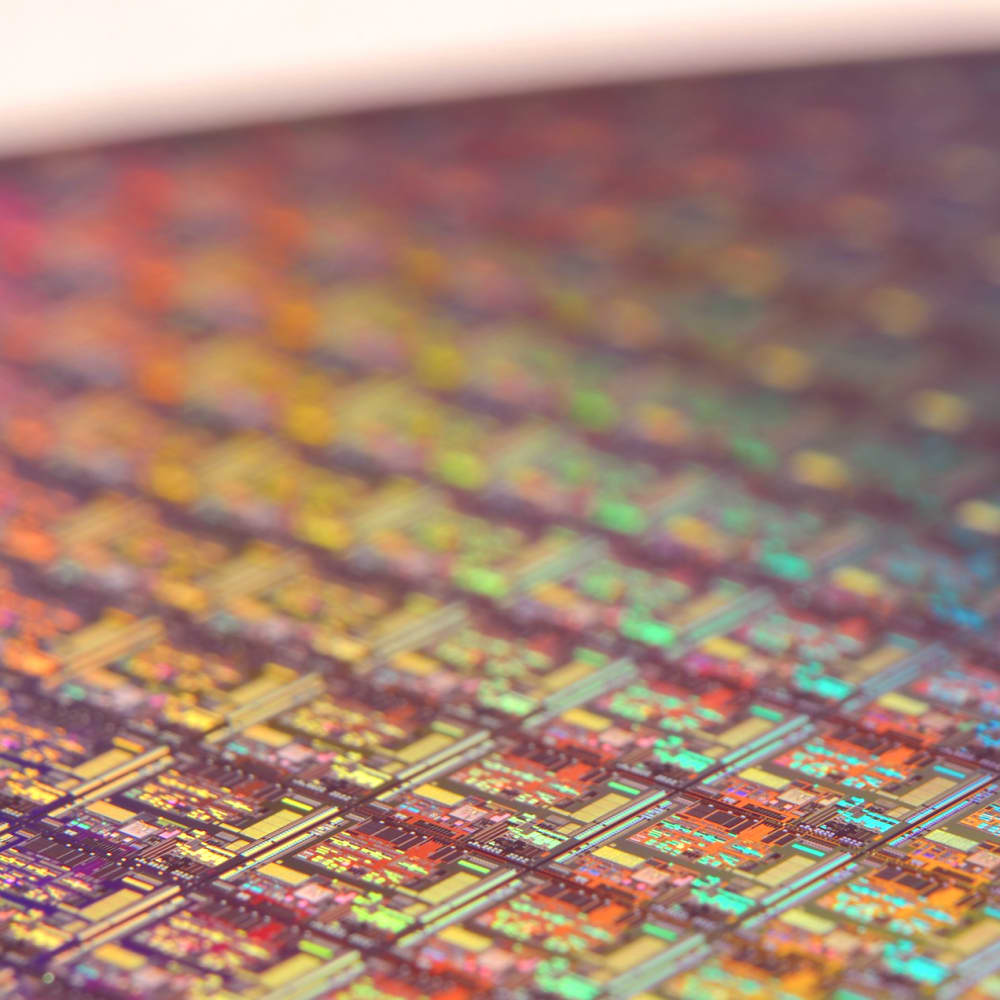

- Corrosive Gases: Facilities like data centers, petrochemical plants, and manufacturing units are susceptible to corrosive gases that can damage sensitive equipment. Gas-phase filtration protects against these gases, preventing corrosion and extending the life of electronic components and machinery.

- Environmental Impact: Gas-phase filtration also helps in reducing the environmental footprint of businesses by minimizing the release of harmful gases into the atmosphere, contributing to a cleaner and more sustainable environment.

Applications Across Industries

- Manufacturing: Toxic gas removal systems, Emergency gas scrubbers, Odour control

- Healthcare: VOC removal units, corrosion monitoring and Control of medical equipment and machinery,

- Commercial Buildings: Odour control for Waste water treatment plant, Corrosion monitoring for server rooms.

- Data Centers: Real time corrosion monitoring, Corrosion control by standalone filters for data cards and critical electronic components.

These applications are not limited to these specific industries but are more in demand as mentioned.

As urbanization and industrialization are evolving the presence of industries could be very near to your doorsteps and so will be the sources of pollution.

Gas-phase filtration is a vital component for businesses aiming to improve air quality and ensure the safety of their environments. It offers numerous benefits, including enhanced air quality, health protection, operational efficiency, and regulatory compliance. Evaluate your current air quality solutions and consider the advantages of integrating gas-phase filtration systems. Expertise in this field can guide you in selecting the optimal solution for your business needs.

For any further assistance and to explore how gas-phase filtration can benefit your business, you may reach out to us via Contact us.