Relationship Between Corrosion Control And Revenue In Data Centers

Published : 25 Jul 2022

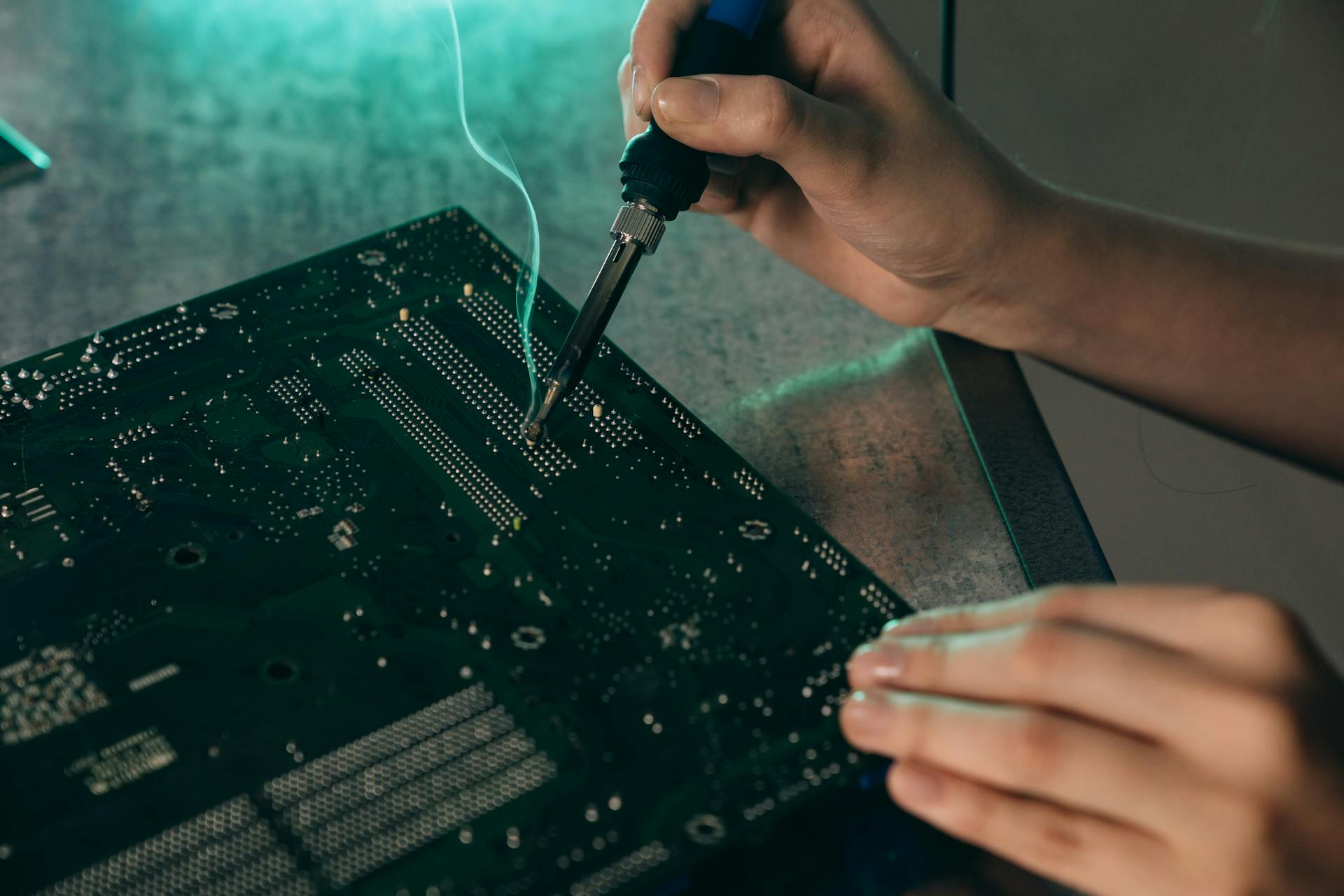

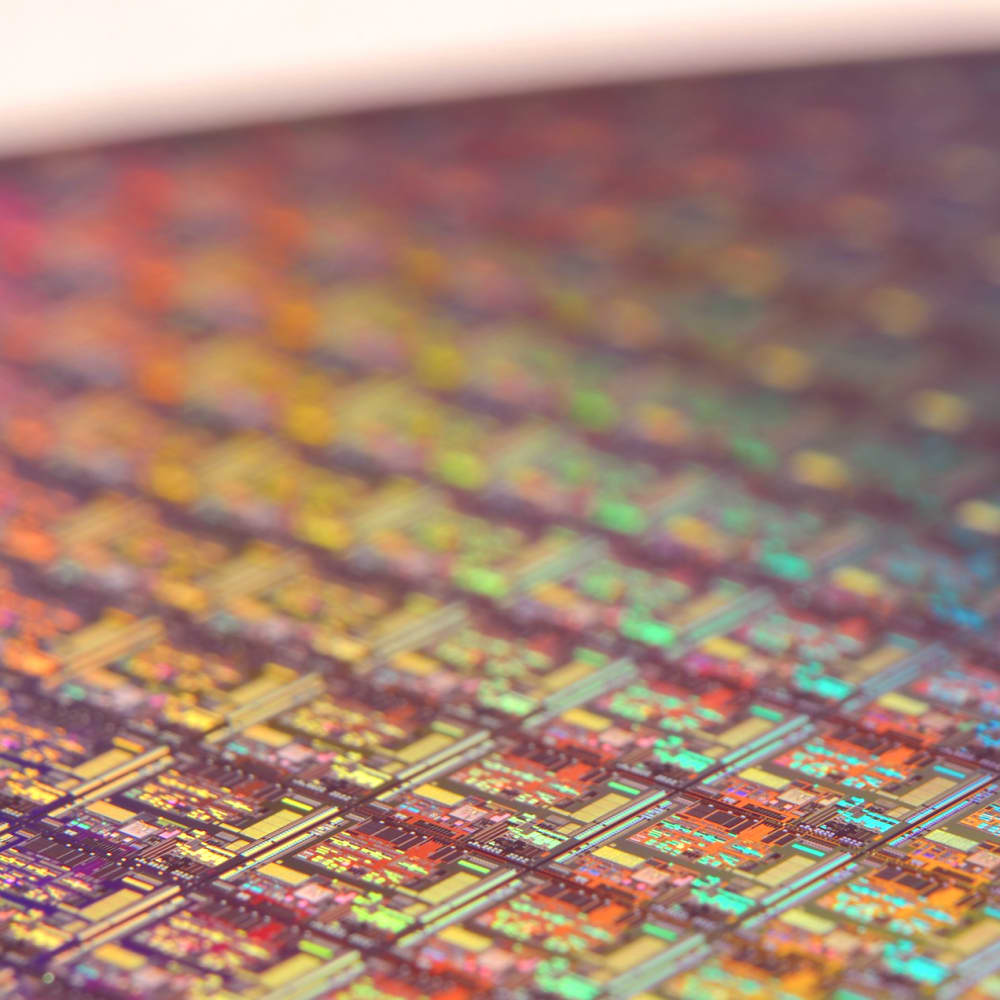

Corrosion is an everlasting problem faced by companies that depend on electronics. The position of facilities like data centres, server rooms and critical control rooms near to any industries or sewage treatment plants makes the equipment more susceptible to corrosion. The introduction of lead-free regulations on electronics has made electronics more sensitive than ever. The major reason why electronic corrosion became persistent is because we cannot simply avoid it. It is impossible to maintain a safer operational environment without adapting additional measures. A single opening and closing of a door can introduce contaminants inside the data centre.

Corrosion management for clean air rooms is directly dependent on the revenue of the facility. Corrosion monitoring and control can be considered as investments rather than expenses. In this article let us see how we can reduce unnecessary costs by employing corrosion control.

Factors affecting revenue

Maintenance cost

Preventing corrosion can increase the life of IT equipment significantly. This reduces the need for repairs or replacements. The yearly cost of maintaining a large data centre can be up to 25 million dollars and 42% of this cost is associated with hardware and software maintenance. A remarkable amount of money can be saved.

Operational losses

Operational losses are due to the abrupt and catastrophic failures due to corrosion. This can disrupt the entire operation if it breaks down. Furthermore, the HVAC system or the free cooling systems for clean air rooms can cause leakage due to pitting corrosion on the coils or heat exchanges which reduces their efficiency of operation. Cataclysmic failures of electronics will increase the downtime which again accounts for huge loss of money.

Loss on capital Invested

Fire hazards are very rare but a constant concern for data centres. Most fires are caused by mistakes done by technicians and are not accounted for by corrosion, but in a worst-case scenario, corrosion can lead to short-circuiting of electronics and dangerous electrical fires. If batteries are nearby, they fuel the fire and burn causing destruction to the infrastructure and possible harm to the employees. The chemicals used to mop the floors such as bleach has chlorine compounds which are contaminants causing corrosion to IT equipment. This will damage the electronics along with the gases coming from the outside if no corrosion management is adapted.

A little investment made on corrosion management for your facility can save a crucial amount of money from expenses thereby increasing the overall revenue of the facility. We at AQOZA technologies deal with handling all sorts of gases causing electronic corrosion and help your business to monitor and identify these gases with our corrosion monitoring units. Being a specialist vendor in gas phase filtration and monitoring, AQOZA offers optimum-performing corrosion control units to various industries. Get in touch with us to know more!!!