Why is Coconut Activated Carbon preferred for Air & Odour purification?

Published : 18 Feb 2021

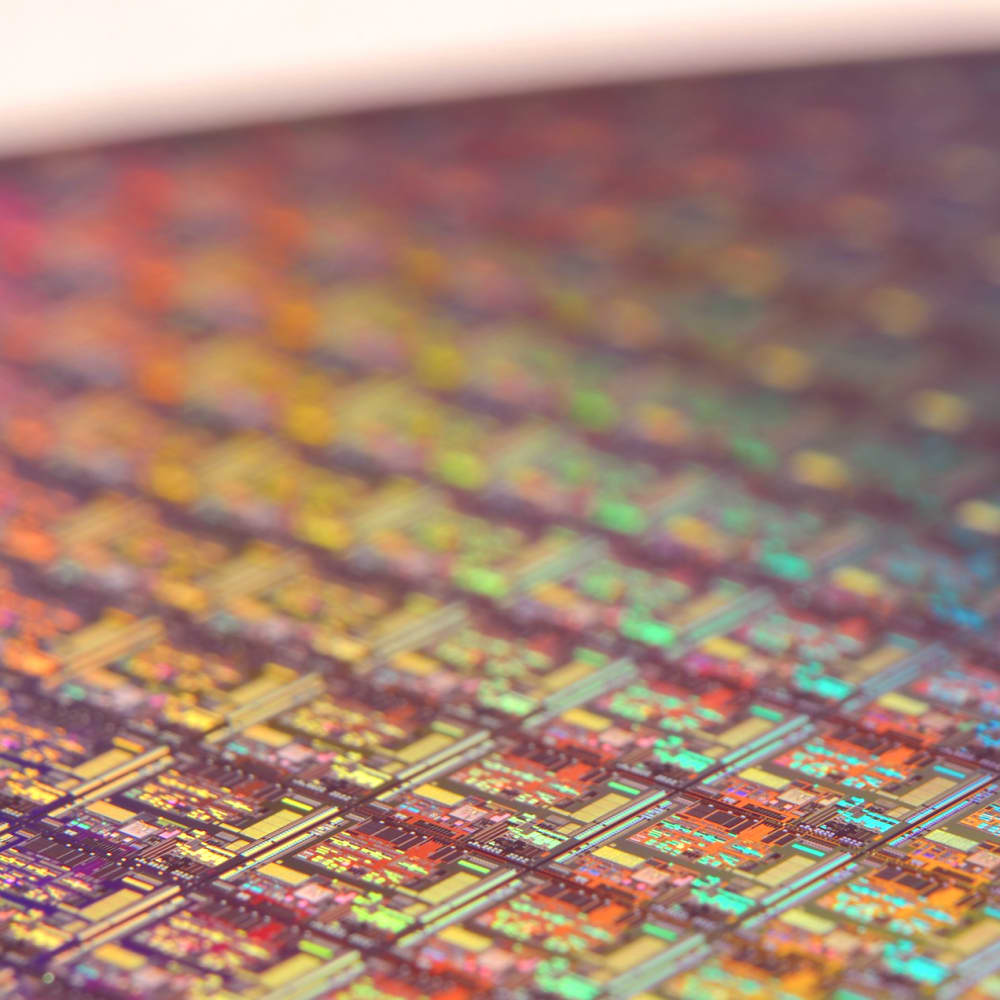

Have you ever thought of why activated carbon is widely being used for air purification? The simple answer is 1gm of activated carbon has a surface area up to 3,000 sq meters to capture the odorous air molecule, that’s equal to the area of football stadium. Confused? When charcoal is treated with oxygen, it will open millions of tiny pores between carbon atoms. These so called active or activated carbon with its increased adsorption capability are widely used for purification water and air.

What is activation process in activated carbon?

Activation is a process in which carbon is made porous to the extent that 75% of its volume is filled with empty space. The density of carbon thus gets reduced to 500 kg/m3 from 2.15 kg/m3, this is achieved by administering steam to red hot charcoal. Other similar molecules can also be used for this process. Activation is done with chemicals also, but the extent of porosity generated by steam is much more compared to chemical activation. This is the reason why activated carbon is used as an adsorbent; no other material can develop so much empty space by such a simple process.

Zeolite – another common adsorption media:

Another common adsorbent is zeolite. Even though we have five varieties of zeolites available, none of them is comparable to activated carbon as far as porosity is concerned. The concept of porosity generation is not significant for these materials. Whatever porosity is generated at the time of its preparation is the final. So, the next alternative is carbon only.

What are the different sources of activated carbon?

Activated carbon is available in three grades depending on the pore diameter namely:

a) Coconut

b) Coal

c) Wood

Coconut carbon is made from coconut shells by activation process. Coconut has micro pores which means that the pore diameter of coconut activated carbon is less than 2 nm. On the other hand, coal has mesopores, having a pore diameter in the range of 2-50 nm and finally wood carbon has the pore diameter of more than 50 nm. These three carbons have different applications.

All molecules having diameter in the micro range will be in the gaseous form as the molecular attractive forces cannot withhold it from escaping to the gaseous form. Since the pore diameter of coconut carbon comes in this range, coconut based activated carbon will be the best one to capture these molecules and hold it firmly without allowing to escape.

The next high boiling molecules will have higher dimensions so that it will come in the meso range. These molecules are mostly low-boiling liquids. The pore diameter of coal carbon mostly falls in this range. So, coal based activated carbon is used to absorb vapours of low molecular liquids and it is widely used for water purification. Finally, wood carbon having macro size pores are suitable for adsorbing bigger or longer molecules. Usually dyes fall in this region. So, wood based activated carbon finds best application in decolorizing a variety of liquids.

Thus, coconut activated carbon is the best material for air purification & odour control. For all practical purposes it is better to use activated coconut carbon as the filter for air depending upon the contaminants. For increasing its capacity of adsorption, chemicals are impregnated in the carbon, as carbon is inert to these chemicals unlike other common base materials.

For the removal of acidic vapours like Hydrogen sulphide from air we can use carbon impregnated with basic or alkaline materials like hydroxides or carbonates of alkali metals. Activated carbon are widely used for removing Hydrogen sulphide Odorous gases from wastewater treatment plants. For the elimination of basic gases like ammonia or amines acidic materials are impregnated. Certain neutral materials like carbon monoxide are best absorbed by transition metals like Palladium or Platinum or even by certain salts of 3d transition metals also.

For the absorption of acidic, basic, and neutral gases simultaneously certain transition metals of the 3d series are the best. For the removal mercury sulphur impregnated carbon is used wherein mercury gets converted to naturally occurring cinnabar (HgS). All these pollutants are neutralised in the pores of carbon itself and nothing comes out. Such a system is not applicable to any other adsorbents because all other adsorbents react with the pollutants unlike carbon which is inert to the pollutants.

As all pollutants are converted to harmless materials, in the pores of carbon itself there is no requirement for waste-treatment as is required for all other adsorbents. In addition, being a natural material of plant origin, it will not give out any obnoxious materials like coal. All these factors make coconut carbon the best materials for treatment of air purification, odour controller system, toxic gas removal, disinfection management and VOC removal applications.

At AQOZA, we manufacture wide range activated carbon and filtration systems for Odour & Gas removal applications. And we have the capability to customize even small amount of adsorption media for odour & VOC purification applications.

May please explore here to know all the Green Tech-solutions available at AQOZA. You can also connect to AQOZA subject matter experts for future assistance.

Also Read:

How much Green is Coconut Activated Carbon?

Virgin Carbon Vs Impregnated Carbon