Cooling Systems: A Double-Edged Sword in Data Centers – Corrosion Control and Advanced Protection Technologies

Published : 08 Jul 2025

The increase of data centers and their expansion into regions with higher levels of atmospheric contamination has increased the focus on indoor air quality management.

One critical concern is on the air-side economization. It is a process that introduces outside air to cool IT equipment. While this method is very much a way of efficient energy utilization, it also introduces significant risks by increasing contamination levels, leading to more frequent failures and premature life of IT equipment.

Understanding Corrosion in Data Centres

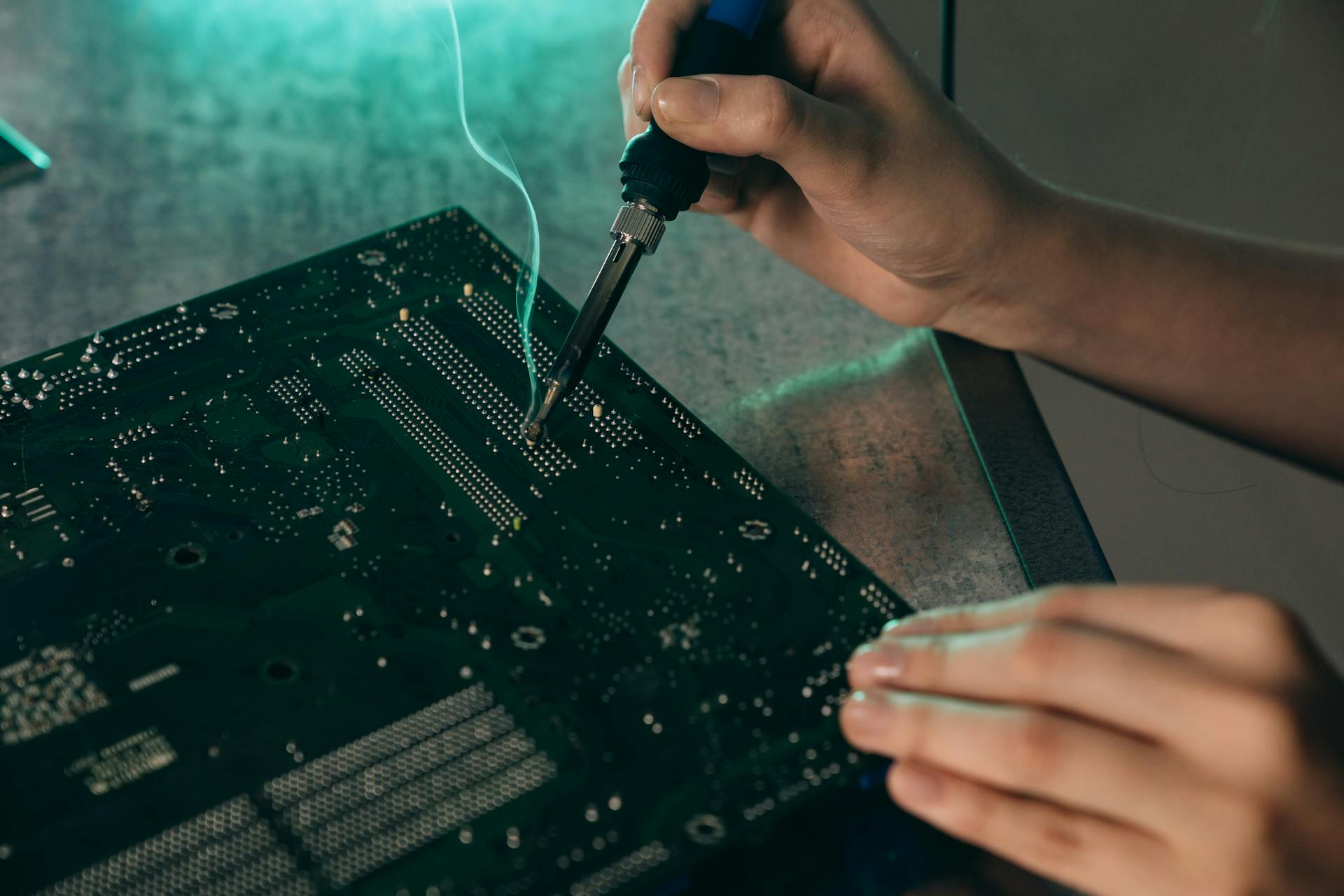

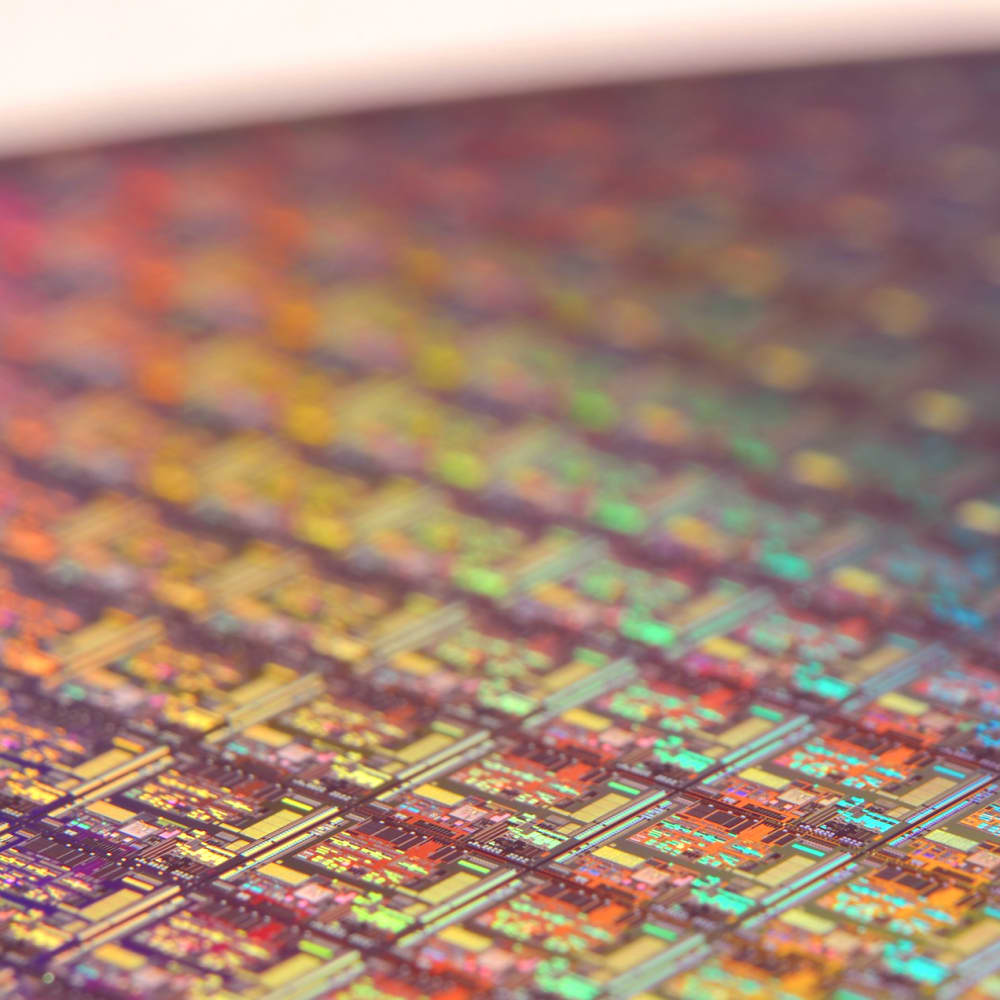

Corrosion in data centres occurs when harmful gases from pollutants enter the facility through air-conditioners in server rooms, control rooms, and other critical areas. This phenomenon, known as micro-electronic corrosion, can lead to equipment failure, increased downtime, and damage to electrical components such as film disks, edge connectors, disk drives by damaging the semiconductors, ICs and the list goes on.

The Dual Role of Air Cooling and The Impact of Air-Side Economization

We can all agree that air cooling is essential for the efficient operation of data centres by eliminating the heat generated by the equipment. However, it also allows infiltrates from outside air to enter the facility. These could be particulate matter ranging in different micron sizes to gaseous contaminants like sulphur dioxide, hydrogen sulphide, and other acidic gases which are invisible to the naked eye.

On one hand air-side economization provides free cooling, on the other it generates corrosion which degrades the electronic components like circuit boards, leading to electrical circuit shortages and eventually resulting in system failures. Even components with immersion silver surface finishes are susceptible to corrosion in high sulphur environments.

Monitoring and Managing Air Quality

To maintain hardware reliability, data center managers must constantly monitor and control the contamination. However, the trend has been to focus only on particulate contaminant filtration, whereas the gaseous pollutants were having a free run and anonymously causing the damage.

Key steps to focus to increase equipment reliability is:

● Measuring Corrosion Rates: Regularly assess the reactivity or corrosion rates inside and outside the data center. Always keep it under G1 classification as per the ANSI/ISA 71.04-2013 standard

● Developing Environmental Profiles: Create a detailed temperature and humidity profile to understand and manage the facility's environment. Keep them in the recommended range

● Installing Pressure Monitors: Use room pressure monitors to maintain a positive pressure environment.

● Adopt the right gas phase filter: ● Adopt the right gas phase filter: Based on the corrosivity levels, implement the right filtration solutions to trap the gases causing the corrosion which ensures the atmosphere will be under G1 classification at all time.

The Need for Effective Filtration

Properly designed filtration systems are crucial to eliminating risks, saving on maintenance and electrical costs, and preventing corrosion. Experts recommend using gaseous contaminant removal air filters to provide maximum protection to both the equipment and the facility.

Corrosion Control Solutions for Data Center Reliability Corrosion Control Solutions for Data Center Reliability Corrosion Control Solutions for Data Center Reliability Corrosion Control Solutions for Data Center Reliability Corrosion Control Solutions for Data Center Reliability

While air cooling is inevitable for the efficient operation of data centers, it also introduces significant risks by allowing contaminants to enter the facility. By implementing real-time corrosion level monitoring and gas phase filtration systems for corrosion control, data center managers avoid these risks, ensuring the long-life and reliability of their IT equipment. Utilizing corrosion control technologies are essential steps for effective corrosion control and prevention. As the industry continues to evolve, understanding cause of micro-electronic corrosion and implementing advanced corrosion control solutions place a crucial role in ensuring data center reliability.

Don’t hesitate to speak with the experts.

RELATED POSTS

- Read about the gases causing corrosion of electronics in data centers.

- Explore our corrosion monitoring and corrosion control units.

- Find more on corrosion control